Crushing wall: The crushing wall is an important part of the cone crusher. It is composed of the frame, horizontal shaft, moving cone, balance wheel, eccentric sleeve, lower crushing wall, hydraulic coupling, lubrication system, hydraulic system, and control system. Cone crusher. Also known as: crushing wall, fixed cone lining plate, cone broken lining plate, cone crusher lining plate, static cone, fixed cone, crushing plate.

The rolling wall is the main component that runs together with the crushing wall in the cone to break the material. It is also called the fixed cone because it is fixed. When the cone is broken in operation, the broken wall will move in trajectory, and the distance between the broken wall and the rolling mortar wall will be close to and away from, so as to squeeze the broken material, and part of the material will be discharged from the open side discharge port. The rolling block wall has a U-shaped screw on the adjusting ring, and zinc alloy is injected between the two to make it tightly combined. When the rolling block wall is newly installed or replaced, after working for 6 to 8 hours, check its fastening condition and tighten the U-shaped screw again. The following are several common high manganese steel cone crusher liner introduction:

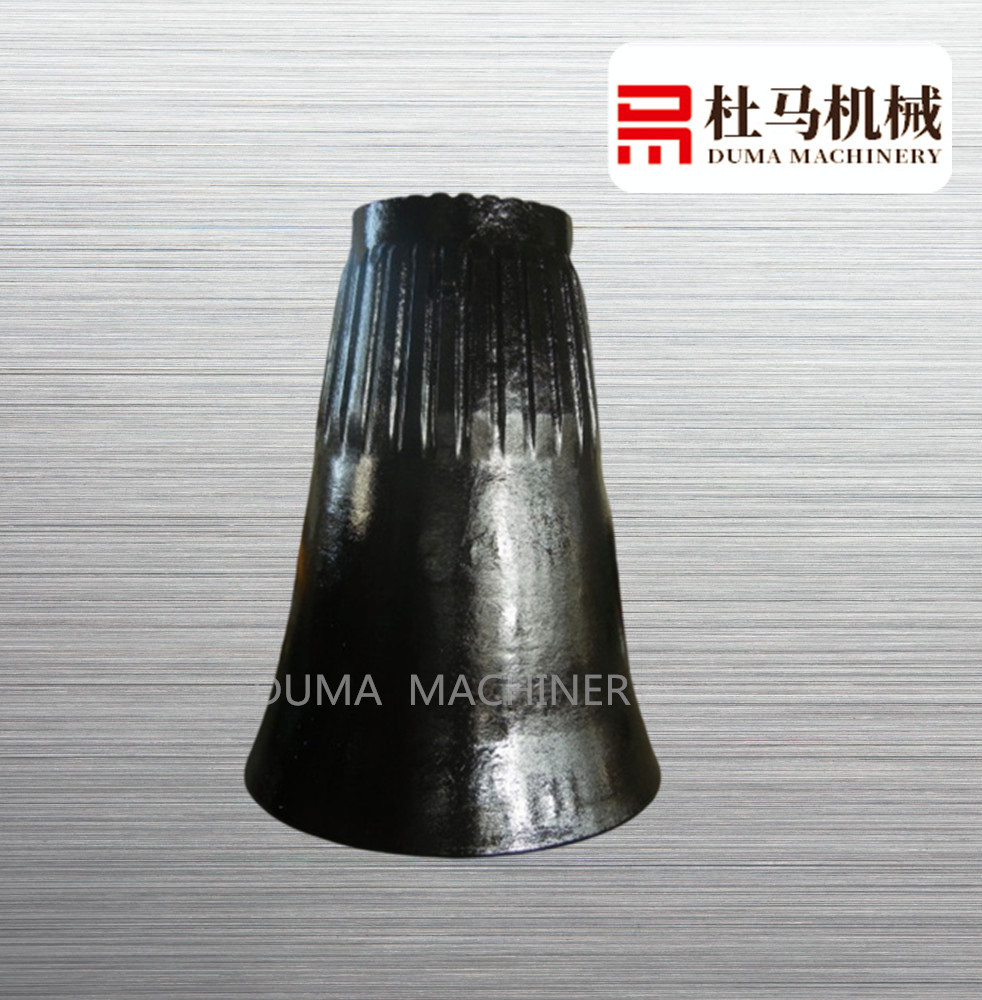

Manganese 13(Mn13) rolled mortar wall broken wall

Mn13 has high tensile strength, plasticity and toughness and non-magnetic, even if the parts wear to a very thin, still can withstand a large impact load without rupture, can be used for casting a variety of impact resistant wear parts.

Manganese 13 chromium 2(Mn13Cr2) rolled mortar wall broken wall

The use of Mn13Cr2 materials, that is, while reducing the content of C and Mn in traditional high manganese steel, the addition of Cr element, makes up for the defect of insufficient toughness of traditional high manganese steel, and effectively prolongs the service life of wear-resistant parts.

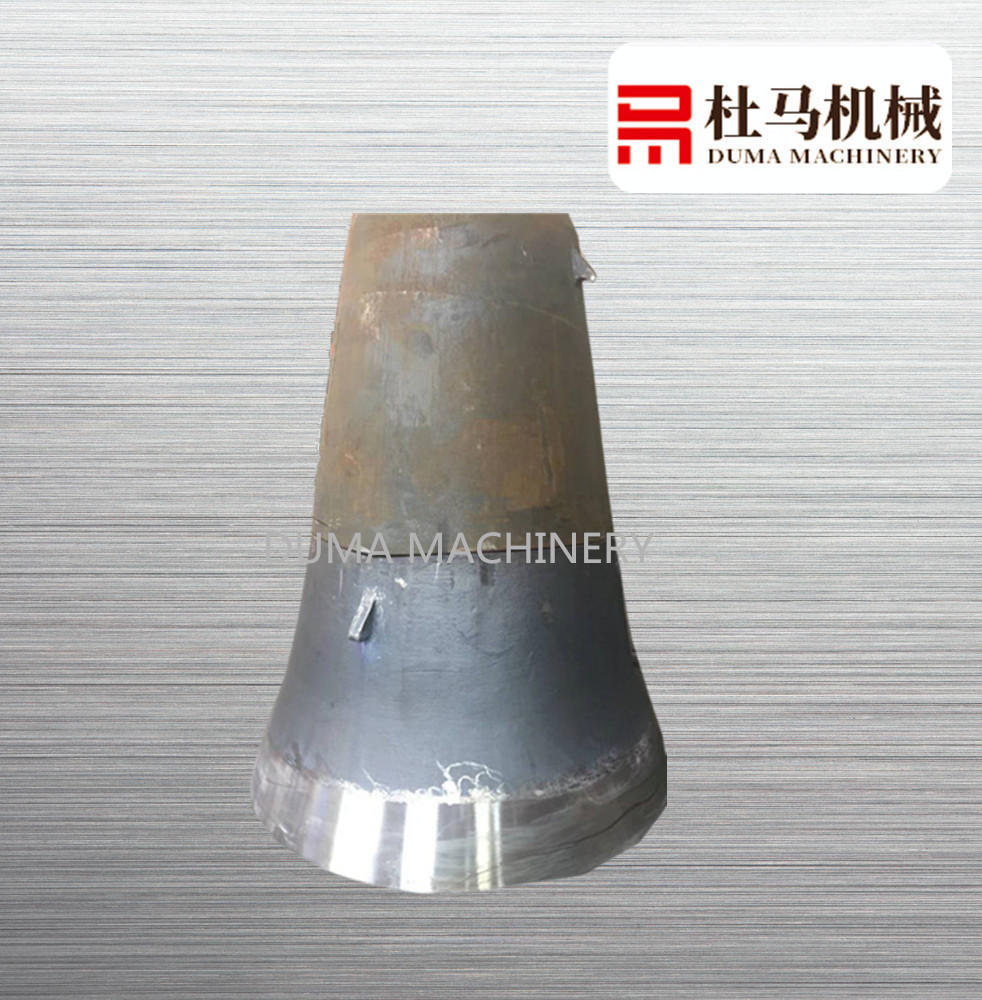

Manganese 18(Mn18) rolled mortar wall broken wall

Casting wear-resistant manganese steel is the oldest and most widely used class. In particular, the standard type of Mn18 high manganese steel rolling mortar wall, manganese and carbon content is high; The cast structure of steel is austenite and carbide, after 1050 ℃ water toughness treatment, most of the carbide solid solution in austenite.

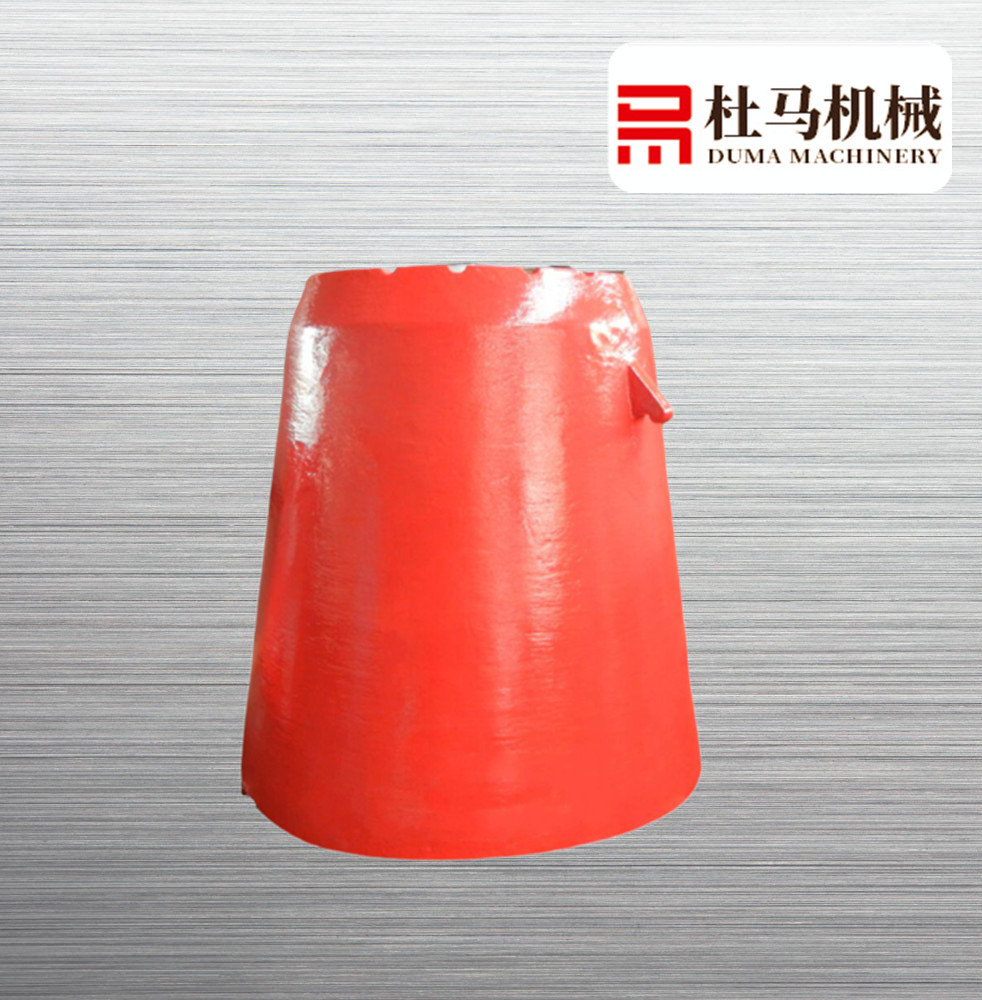

Manganese 18 chromium 2(Mn18Cr2) rolled mortar wall broken wall

The material is made of Mn18Cr2 material, which is treated by compound modification to refine grains and purify grain boundaries. Control solidification mode in casting and optimize heat treatment process. The casting has high hardness, good toughness, impact resistance and wear resistance, and is suitable for large and medium-sized cone crusher.

Manganese 22 chromium 2(Mn22Cr2) rolled mortar wall broken wall

The Mn22Cr2 cone broken wall rolled mortar wall developed by the company for American customers has been approved by American customers after their production and testing.

New composite rolling mortar wall crushing wall

The use of low-cost high manganese steel or ultra-high manganese steel for large wear-resistant parts of the matrix material, in their working parts of the composite inlaid hard alloy, so that the wear surface of the bimetal composite wear-resistant parts has excellent wear resistance, non-wear surface has excellent plasticity and impact toughness, reducing the wear of the matrix high manganese steel, so that the cone broken mortar wall service life is greatly improved.

Jiangxi Duma Machinery Manufacturing Co., Ltd. mainly produces jaw crusher accessories (tooth plate, guard plate, pressure plate, etc.), cone crusher accessories (rolling mortar wall, crushing wall, material distribution plate, pressing sleeve, etc.), ball mill accessories (lining plate, steel ball, etc.), counterattack crusher accessories (plate hammer, lining plate, etc.), hammer crusher hammer head, and various wear-resistant alloy accessories.

The company adheres to the market-oriented, quality first, customer first for the business purpose, in accordance with the ISO9001 quality system standards to establish a sound quality management system, cultivate a high-quality technology development and production management team, its advanced management concepts and rigorous management measures to ensure product quality and price advantage.

Warmly welcome domestic and foreign merchants to come, call letter business negotiations, we will provide you with quality service.