Hammer head: Hammer crushers are divided into single-stage hammer crushers, high-efficiency hammer crushers, sand breakers, vertical shaft hammer crushers, reversible hammer crushers, and ring hammer crushers. It is metallurgy, building materials, chemical industry and hydropower. One of the main equipment for finely crushing limestone, coal or other brittle materials below medium hardness in industrial sectors has the characteristics of large crushing ratio, high production capacity, and uniform product size.

We can provide wear-resistant parts for various types of hammer crushers, such as crusher hammer head, coal crusher ring hammer, counterattack plate hammer, counterattack lining plate, grate plate, grate strip, sieve plate and other accessories, and can also manufacture products of different materials according to the drawings provided by customers. Jiangxi Duma all kinds of hammer parts model is complete, good wear resistance, long service life, large manufacturers trustworthy!

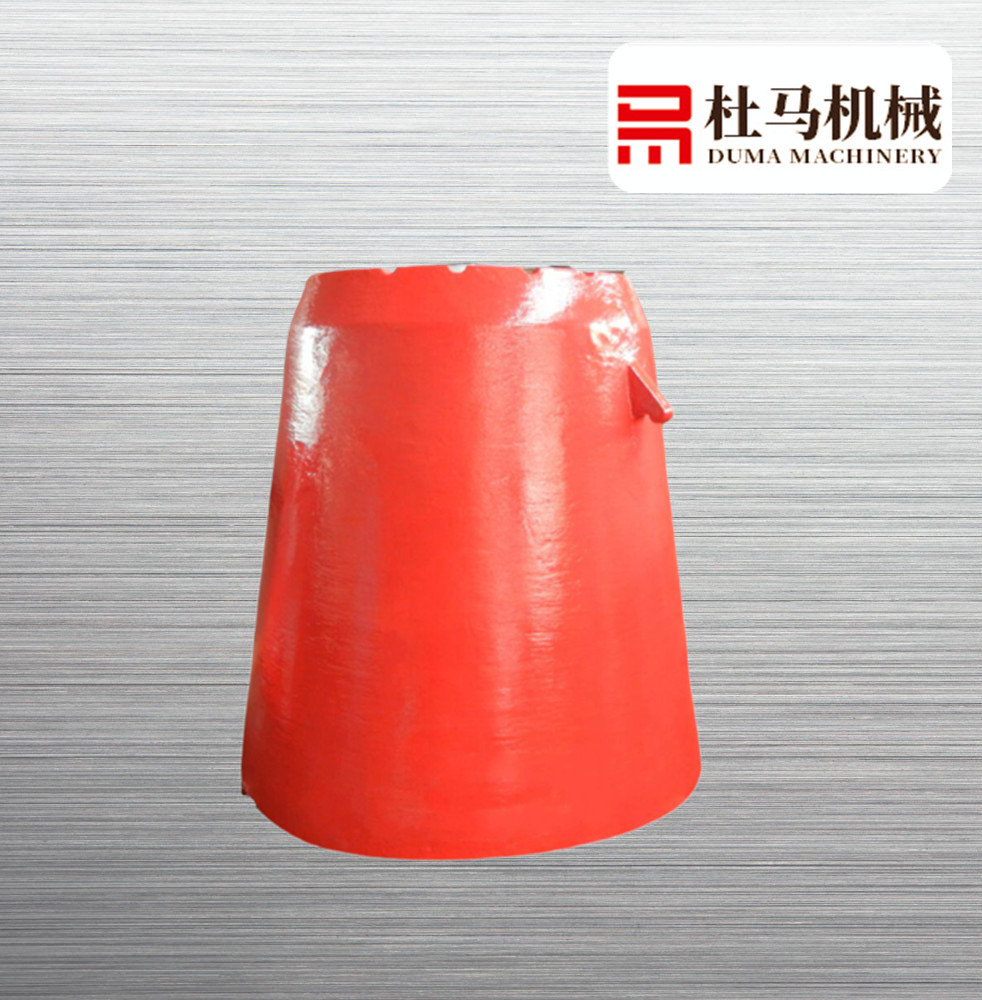

High manganese steel hammer head

High manganese steel and ultra-high manganese steel casting (Mn13,Mn13Cr2,Mn18,Mn18Cr2) are combined with advanced production technology to produce high manganese steel hammers, ultra-high manganese steel hammers and high manganese steel alloy hammers to adapt to different service conditions of hammer crushers, so that the crusher hammers can achieve performance, are suitable for crushing pebbles, coal gangue, limestone and other materials, and become the first choice of hammers for many cement and sandstone enterprises.

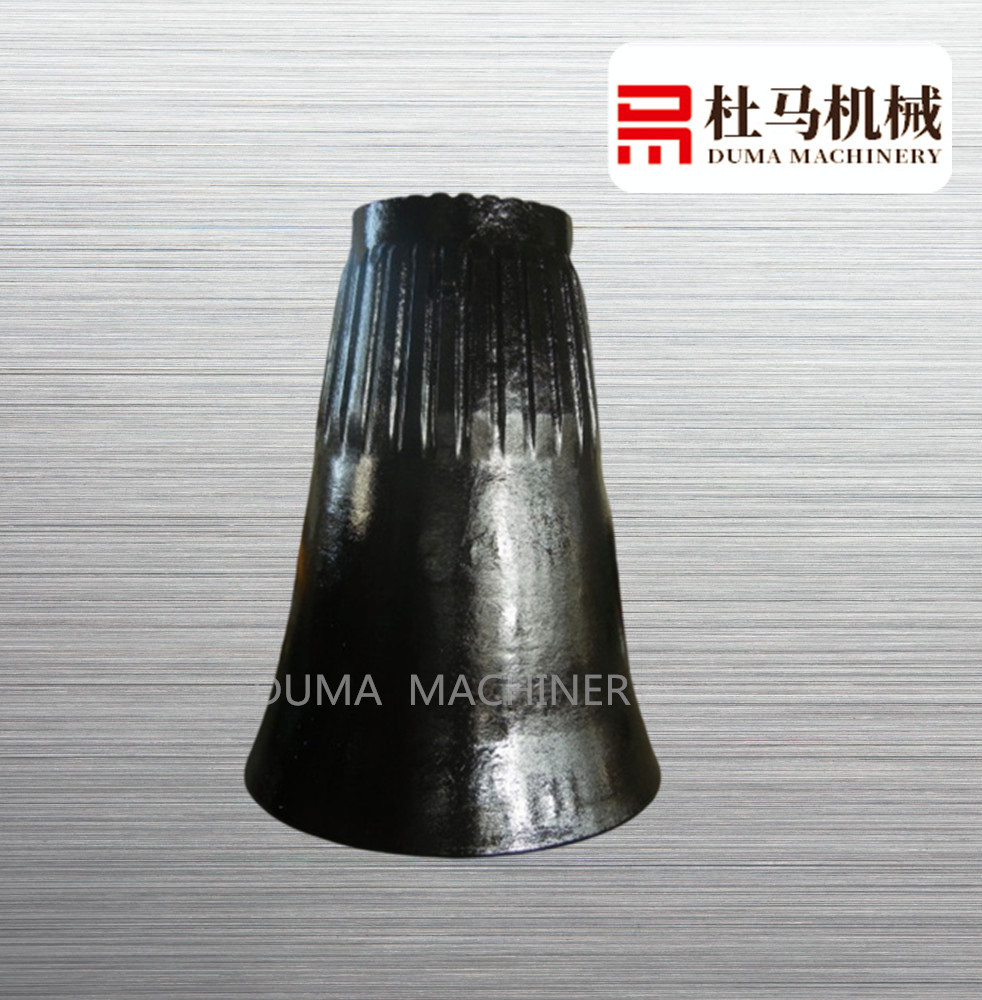

Bi-metal composite hammer head

Adopts the contemporary advanced composite casting technology, the hammer head adopts high chromium cast iron with good wear resistance, and the hammer handle adopts the most tough wear-resistant alloy steel, which integrates toughness and wear resistance, so that the product is both wear-resistant and not broken. It is the perfect combination of steel and iron, so that the product has good wear resistance, impact resistance, safety and reliability.

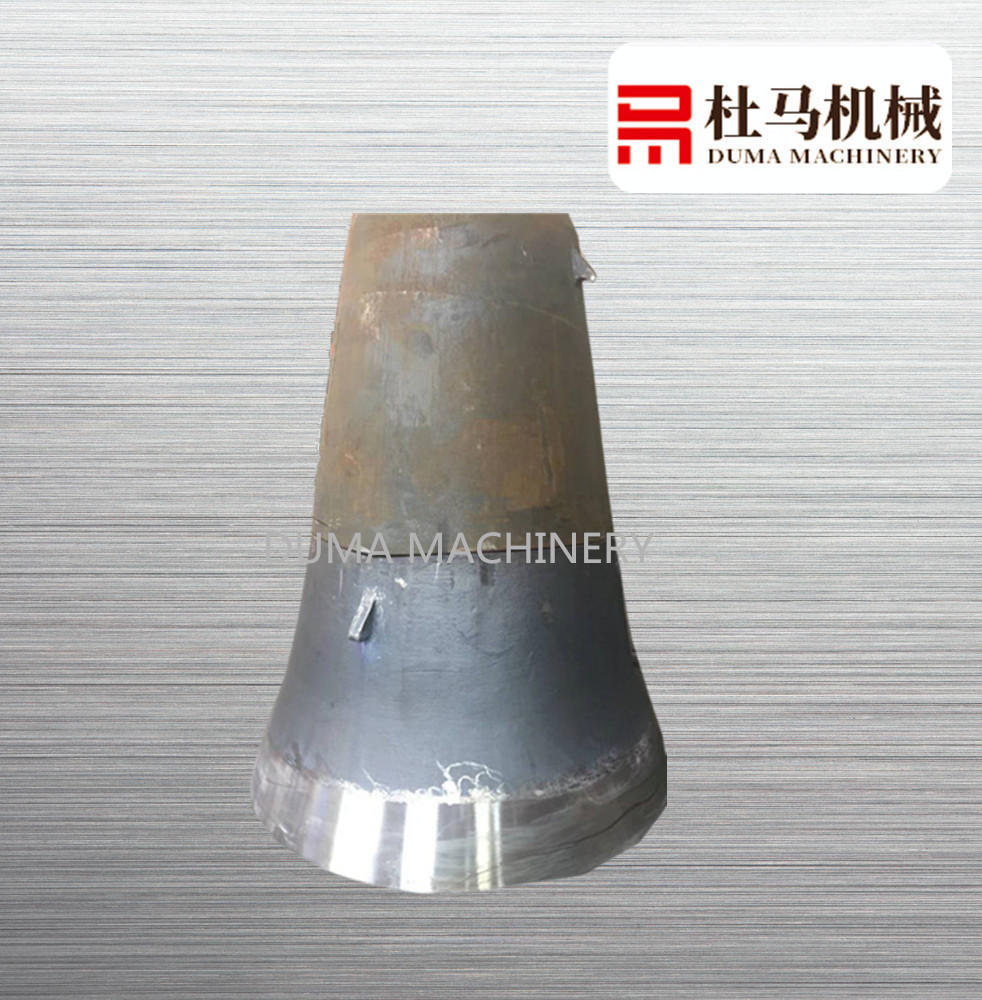

High chromium alloy hammer

It is cast by high chromium composite material. Compared with ordinary high manganese steel hammer head, it has the characteristics of high hardness and high wear resistance. The high hardness martensite matrix in the hammer head of the sand making machine strongly supports carbide particles and avoids Carbide falls off from the wear surface during work, ensuring the high wear resistance of the material.

Inlaid carbide hammer head

Also known as the big gold tooth wear-resistant hammer, the production of tungsten titanium alloy crusher hammer, the use of special technology, in the alloy hammer hammer working face insert casting hard alloy round rod, alloy block and other ways of casting processing, both high anti-wear effect, and reliable safety performance. Effectively solve the contradiction between hardness and toughness, so that it can adapt to a variety of complex and harsh working conditions.

Ring hammer of coal crusher

The ring hammer coal crusher is a series of coal crushing machinery specially designed for the coal handling system of thermal power plants. The ring hammers of the coal crusher are divided into: ring hammer crusher tooth hammer, ring hammer crusher ring hammer, Jiangxi Duma By optimizing the material composition, designing a reasonable casting process, and combining with the heat treatment process strengthening measures, a new type of modified high manganese steel ring hammer has been developed, which has good wear resistance and comprehensive mechanical properties.

Jiangxi Duma Machinery Manufacturing Co., Ltd. mainly produces jaw crusher accessories (tooth plate, guard plate, pressure plate, etc.), cone crusher accessories (rolling mortar wall, crushing wall, material distribution plate, pressing sleeve, etc.), ball mill accessories (lining plate, steel ball, etc.), counterattack crusher accessories (plate hammer, lining plate, etc.), hammer crusher hammer head, and various wear-resistant alloy accessories.

The company adheres to the market-oriented, quality first, customer first for the business purpose, in accordance with the ISO9001 quality system standards to establish a sound quality management system, cultivate a high-quality technology development and production management team, its advanced management concepts and rigorous management measures to ensure product quality and price advantage.

Warmly welcome domestic and foreign merchants to come, call letter business negotiations, we will provide you with quality service!