Jaw crusher is mainly used for medium size crushing of various ores and bulk materials, and is widely used in mining, smelting, building materials, highway, railway, water conservancy and chemical industries. The maximum compressive strength of the crushed material is 320MPa. Jaw crusher accessories can also be called jaw crusher vulnerable parts, is an important part of the jaw crusher; we can provide wear parts for various types of jaw crusher, such as jaw plate (moving plate, fixed plate), elbow plate, side guard plate, etc., can also be provided according to the customer's drawings to manufacture products of different materials.

High manganese steel jaw plate

High manganese steel is the traditional material of jaw crusher jaw plate, it has good toughness, also has good deformation hardening ability. Material: Mn13, Mn13Cr2 ,Mn18,Mn18Cr2 (I. e. ultra-high manganese) or special ingredients according to working conditions.

Medium manganese steel jaw plate

Due to the low initial hardness and low yield strength of high manganese steel, its work hardening is insufficient under non-strong impact conditions, and it is easy to flow and be cut. In order to improve the service life of the jaw plate, the medium manganese steel was developed. When dealing with soft materials, the use of medium manganese steel is better. When the medium manganese steel jaw plate is crushed on a small crusher to crush limestone, the life of the medium manganese steel is greatly improved.

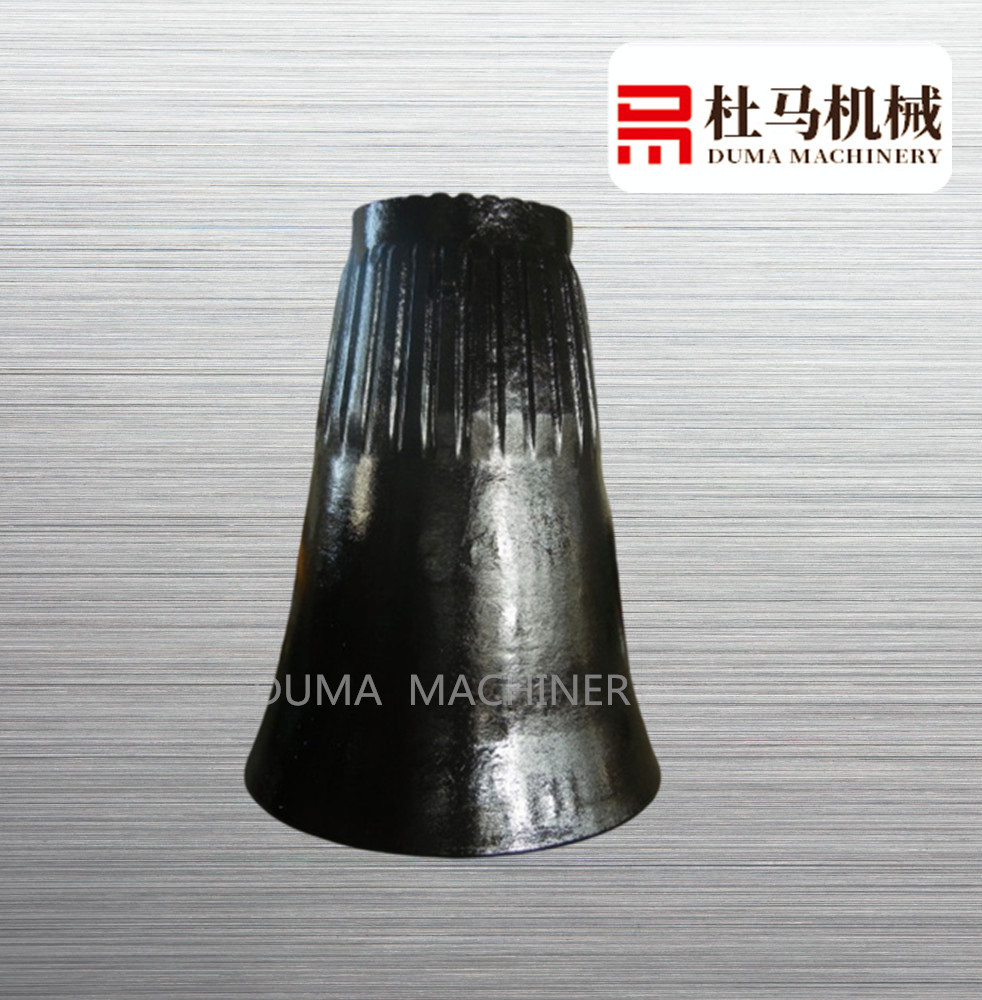

Bimetal composite jaw

According to the working principle and practical application status of jaw crusher, a double liquid bimetal composite casting jaw plate is developed, the working surface is made of alloy steel with high wear resistance, and the lining part is made of cast steel with good impact toughness, giving full play to the special features of various materials. At the same time, the special gating system and casting process ensure the uniformity and integrity of the composite interface, and optimize the performance of the jaw plate.

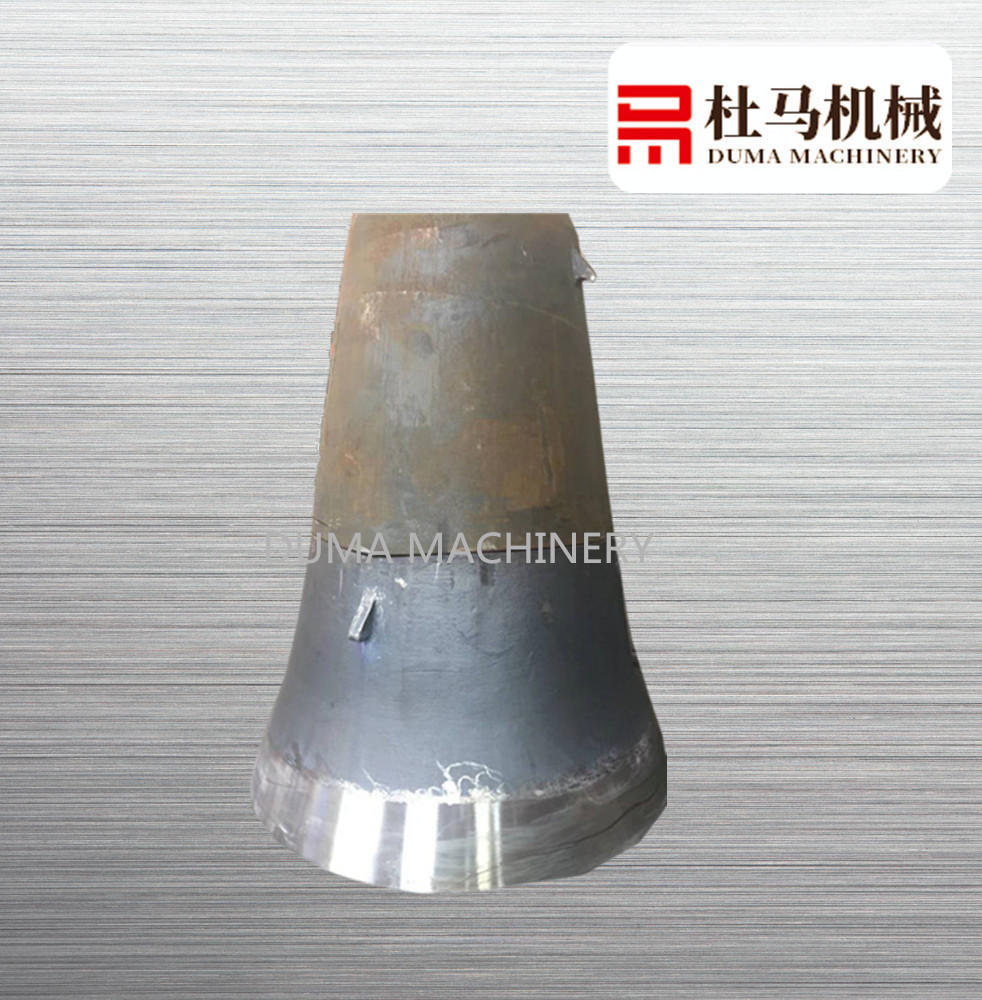

low alloy cast steel jaw plate

Medium-carbon low-alloy cast steel is a kind of wear-resistant material, mainly because of its high hardness and appropriate toughness, it can resist the cutting effect of the material and the fatigue spalling caused by repeated extrusion of the material, so it shows good wear resistance. At the same time, the hardness and toughness of medium carbon low alloy cast steel can also be changed in a large range by adjusting the composition and heat treatment process to meet the requirements of different working conditions.

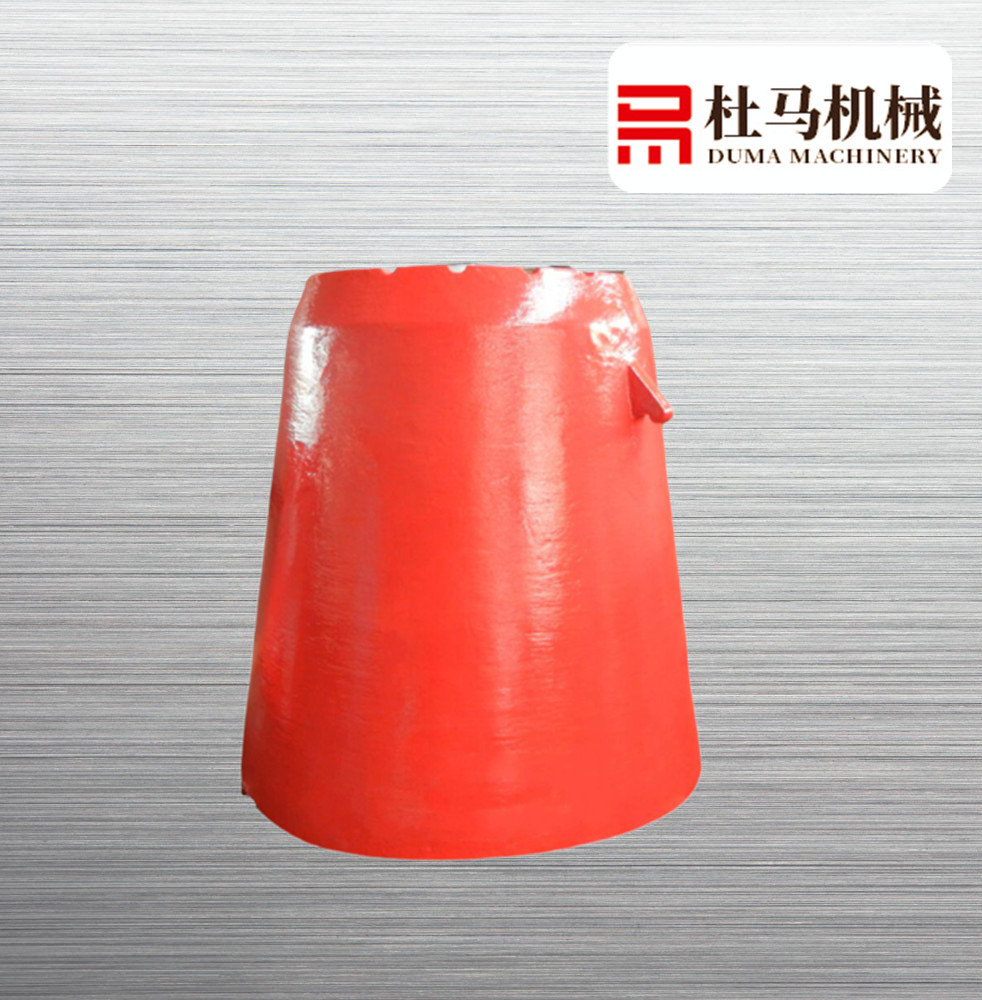

Jaw crusher side guard plate

The side guard plate of jaw crusher is also called fork plate and baffle plate. It is located between the fixed tooth plate and the movable tooth plate. It is a high-quality high manganese steel casting. Generally, there are 2 or 4 pieces per machine. This product is a kind of high-strength wear-resistant steel, which can effectively protect the body and prolong the life of the frame.

When Jiangxi Duma Machinery Manufacturing Co., Ltd. invested in the production of mining machinery parts, it determined the positioning direction of "high, precise and accurate", and the products have won praise from customers all over the world. The main products are: jaw crusher tooth plate, side guard plate, pressure strip; cone crusher rolling wall (fixed cone), crushing wall (moving cone); ball mill, rod mill and other equipment lining plate; impact type, hammer crusher plate hammer, lining plate; metal crusher hammer, sieve strip, lining plate. And other wear-resistant alloy steel parts. The company in line with the quality as the root, integrity-based, innovation as the soul, management as the spirit of the business philosophy, will continue to serve every customer.