What material are jaw crusher liners made of?

Release time:

2025-01-10 08:58

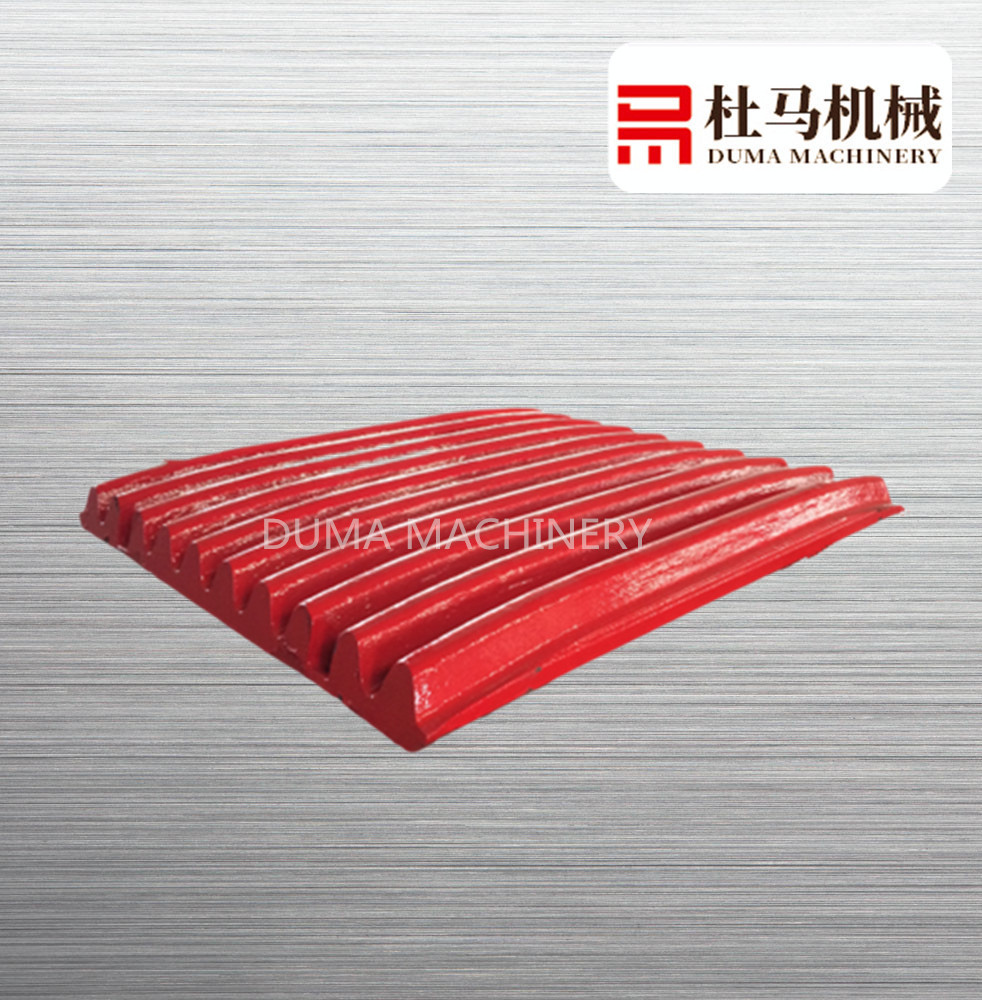

Jaw crusher liners They are important components in crushers, responsible for withstanding the impact and friction from materials. To improve their wear resistance and service life, crusher jaw plates are usually made of various wear-resistant materials. Common materials include austenitic manganese steel, high-strength steel, stainless steel, and tungsten carbide. Each material has its unique advantages and applicable scenarios. The specific choice usually depends on the working environment and material characteristics of the crusher.

Manganese steel

Manganese steel, especially austenitic manganese steel, is Jaw crusher liners an industry standard in manufacturing. A significant characteristic of this material is its ability to increase surface hardness through work hardening when impacted, thereby improving its wear resistance. Manganese steel has a long history of use and is widely used in mining, construction, and other industries, especially suitable for high-impact and high-wear applications. When the surface of a high-manganese steel jaw plate wears, it becomes harder through a natural hardening process, extending the service life of the crusher jaw plate and reducing the frequency of replacement.

High-strength steel

High-strength steel is usually used to protect the crusher's frame and jaw plate structure. Compared with traditional materials, high-strength steel exhibits superior tensile strength and wear resistance, especially maintaining structural stability when subjected to large external forces. This material not only improves the service life of the equipment but also effectively reduces the weight of the crusher, helping to improve the crusher's efficiency. Due to its good fatigue resistance, it can handle long-term, high-load operation, especially suitable for processing harder materials.

Stainless steel

In some special applications, jaw crusher liners may use stainless steel, especially 316L stainless steel. 316L stainless steel has excellent corrosion resistance and can operate stably for a long time in wet or corrosive environments. Although its hardness may not be as good as manganese steel, it is still a choice in some industries with high corrosion resistance requirements, such as the chemical and food processing industries.

Tungsten carbide

Tungsten carbide is currently one of the most wear-resistant materials in jaw crushers, especially suitable for very high-wear working environments. Tungsten carbide has extremely high hardness and can effectively resist various wear and impact, making it the material of choice for processing extremely hard materials. Due to its high hardness, it is usually used on the surface of liners or other severely worn parts, extending the service life of the crusher to a certain extent and reducing maintenance costs.

Jaw crusher liners Made of different materials such as austenitic manganese steel, high-strength steel, stainless steel, and tungsten carbide, the choice of each material is closely related to the working environment, material characteristics, and equipment operating requirements. With the continuous development of crushing technology, jaw crusher plate manufacturers are constantly optimizing the use of these materials and liner design to improve crusher efficiency and extend equipment life.

Jaw crusher liner,Crusher Jaw Plate,High manganese steel jaw plate,Jaw crusher plate manufacturer

Previous Page

Previous Page

RELATED INFORMATION

2025-04-11

60

2025-06-02

60