Jaw Crusher Jaw Plate Full Analysis: 10 Core Knowledge Points - Professional Jaw Plate Factory Technical Guide

Release time:

2025-04-11 08:48

In the fields of mining and construction, jaw crushers serve as core equipment for raw material crushing. The performance of their key component—the jaw plate—directly impacts the overall efficiency. As a professional jaw plate manufacturer, Duma Machinery will provide a comprehensive introduction to jaw plate classification, material properties, and service life optimization solutions.

1. Working Principle of Jaw Crusher

Jaw crushers achieve material crushing through the coordinated action of the movable and fixed jaw plates. The equipment uses a double jaw plate structure design, where the fixed and movable jaw plates form the crushing chamber. This jaw crusher component is widely used in mining and building materials industries.

2. Typical Application Scenarios

As the core equipment for primary crushing, jaw crusher components mainly undertake the coarse crushing of raw materials. Professional jaw plate manufacturers recommend selecting custom jaw plates with appropriate tooth shapes for different material properties.

3. Jaw Plate Structure Analysis

As the core wear parts of jaw crusher components, jaw plates are cast from high wear-resistant alloys. Based on installation location, they are divided into fixed and movable jaw plates, which form the crushing chamber through specific tooth designs.

4. Dual Functions of Jaw Plates

(1) Crushing Function: The movable jaw plate applies compressive force to the material through its tooth structure.

(2) Protective Function: The fixed jaw plate acts as a wear-resistant barrier to protect the main body of the crusher.

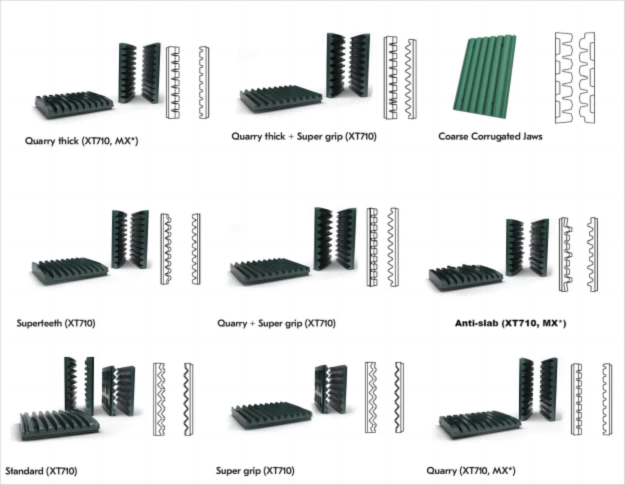

5. Jaw Plate Tooth Shape Classification (Recommended by Professional Jaw Plate Manufacturers)

■ Standard Type (XT710): Basic custom jaw plate

■ Grip Type: Optimized tooth spacing design

■ Quarry-Specific Type: Thickened movable jaw plate design

■ Anti-Agglomeration Type: Asymmetrical tooth height fixed jaw plate

6. Material Selection Guide (Core Technology of Jaw Plate Manufacturers)

√ High Manganese Steel: Commonly used material for movable jaw plates

√ High Chromium Cast Iron: Preferred material for fixed jaw plates

√ Composite Material: Special process for custom jaw plates

Note: Duma Machinery provides customized materials for a full range of jaw crusher jaw plates.

7. Key Selection Factors

Professional jaw plate manufacturers suggest focusing on:

→ Matching degree of movable/fixed jaw plates

→ Cost-effectiveness analysis of custom jaw plates

→ Overall service life of jaw crusher components

8. Wear Mechanism Analysis

Jaw plate manufacturers' research has found that the main wear comes from:

☆ Impact wear on movable jaw plates

☆ Frictional wear on fixed jaw plates

☆ Misalignment of jaw crusher components

9. Service Life Optimization Solutions

Professional recommendations from jaw plate manufacturers:

① Periodic replacement of movable jaw plates

② Wear monitoring of fixed jaw plates

③ Special treatment for custom jaw plates

10. Selection of Quality Suppliers

Duma Machinery, as a professional jaw plate manufacturer, provides:

★ Full range of jaw plate solutions

★ Professional selection guidance

★ Fast delivery service

★ On-site technical support

Choose a professional jaw plate manufacturer to obtain high-quality jaw crusher jaw plate solutions! Duma Machinery's technical team is always available to provide you with custom jaw plate selection advice.

Jaw plate factory,Jaw crusher components,Jaw crusher jaw plate,Palatal plate,Fixed Jaw Plate,Customizable jaw plates

Previous Page

Previous Page

RELATED INFORMATION

2025-04-11

60

2025-06-02

60